I read all comments connected to Potti314 decoding attempt in my Worldwide Decoding Challenge and most people claim that metal model will be easier to decode because of better feedback.

I respect those opinions and I decided to start redesigning process to adopt my PCL mechanism for real CNC stainless steel plus brass model.

I will post here in the future the STEP files for CNC production of my Polish Combination Lock from Steel, Brass and Aluminium just to test your point. It will be however long way to finish it because there is no one yet who would like to co-operate to produce such a lock.

I hope that after redesigning and adopting this to steel CNC production I will find someone to produce such a mechanism.

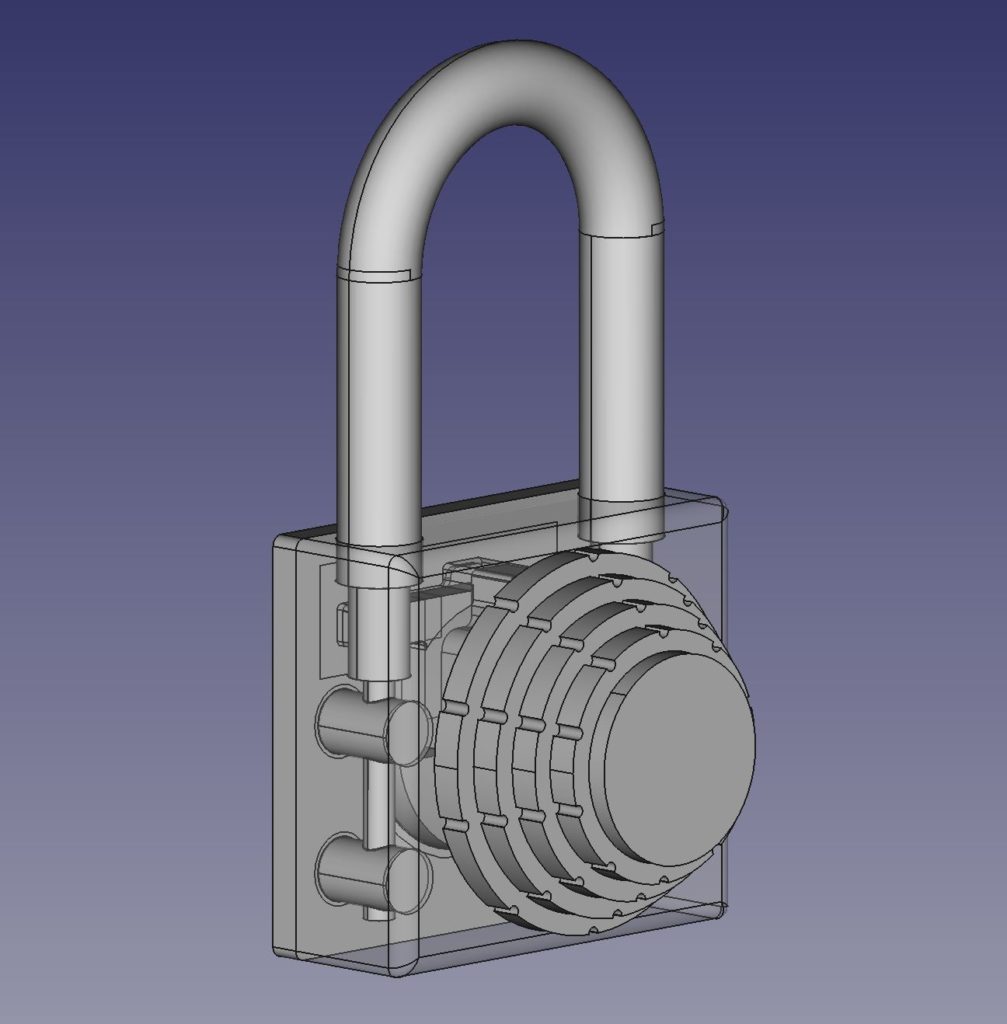

The CNC model will be also in the form of padlock just for testing purpose it is easier to send padlock than safe. It will be much thinner and more precise and I am sure it would be even more difficult for decoding (this is my opinion) . I will stay with 4 wheels x 10 number on each wheel (10 000 combinations) and the numbers will be laser engraved on all knobs (knobs would be step down). There will be clicker as well for more convenient operation. The working parts would be made from brass and the housing and shackle from stainless steel.

IMPORTANT NOTICE: In the final production version the mechanism must be protected against drilling by adding anty-drill discs inside the mechanism covering the internal wheels from both sides (front and back).

If you have any suggestions how the stainless steel model should looks like to satisfy you just let me know. polishlocks@tlen.pl

Meantime the 3D model from plastic is still in the Challenge for acquiring feedbacks.

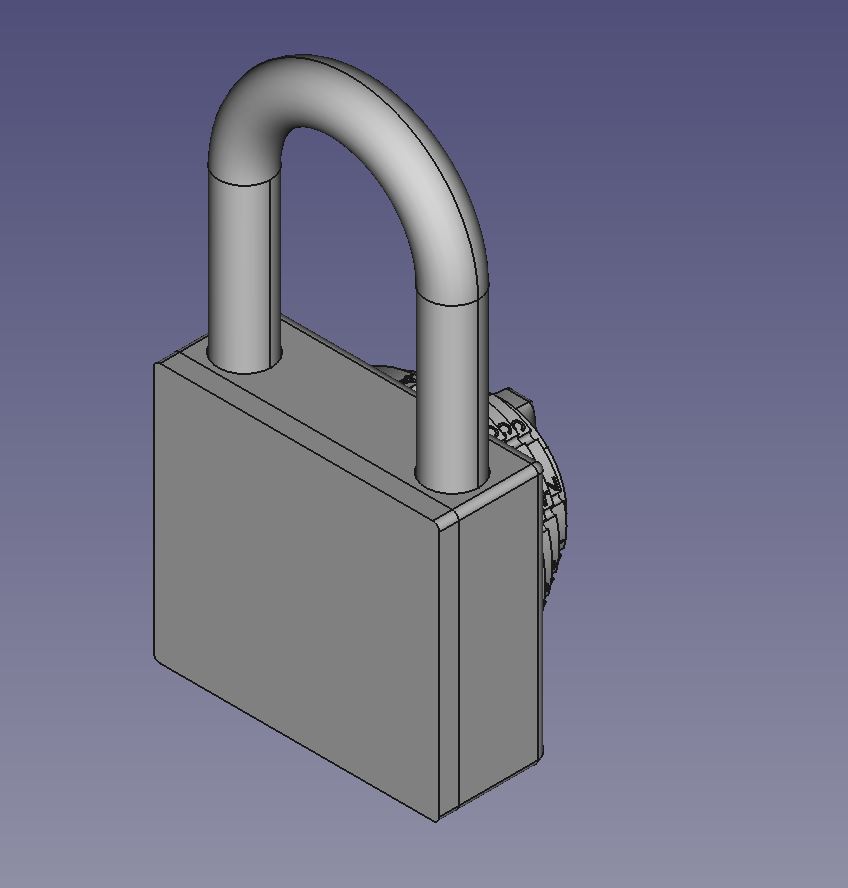

Slowly I designing new mini padlock for CNC process. It will have compact size and 10 000 combinations (there will be 4 wheels and 0-9 on each wheel). The shackle will be 8mm and the body 40x44x36mm. I think this unpickable padlock will be compact and strong and reliable for average user. The code will be easy to memorize. It will be made from brass and steel. If you have CNC machines and you would like to help me in production of the first metal prototype please contact me. Potti314 suggests to replace the mounting Open/Close knob from screwed ring to Seeger ring. So I redesign this is already mounted in below example. Look at the dimensions , this is very small and strong padlock with Polish Combination Lock mounted inside. The final shape is up to us, we can make close or open shackle etc.

3D STEP files ready for CNC below.

Donation for further development: https://www.paypal.me/ZbigniewOlejnik

In real model you need to replace C-CLIP with proper Seeger external mounting ring no 5 and use 2,8mm steel rod as PINS (not included).

Ready for production small padlock printed on Formiga P100 printer in Warsaw University of Technology in Rapid Prototyping Laboratory.

Below few latest graphics : After redesign it looks pretty nice, is small, strong and beautiful. Maybe someone will produce sample unit for testing from Steel, Brass and Aluminium.

Cheers,

Zbigniew